Understanding the Role of 90º Bend With Male Thread in Stainless Steel Piping Systems

Jul 13,2025

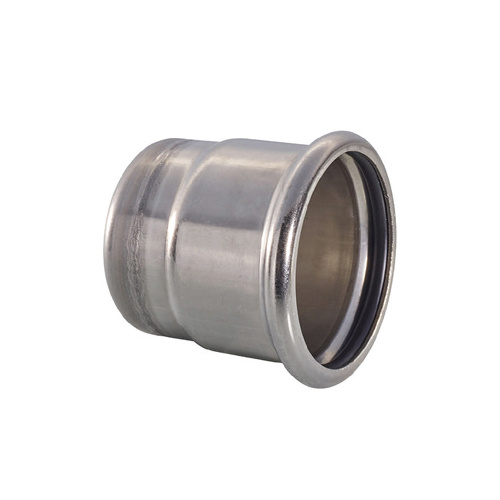

In the realm of construction and decorative materials, particularly in the category of stainless steel piping, the use of fittings is essential for ensuring the integrity and functionality of piping systems. One such critical fitting is the "90º bend with male thread." This component plays a crucial role in facilitating changes in direction within piping systems, allowing for efficient space management and fluid flow.

A 90º bend is designed to enable pipes to change direction smoothly, minimizing the risk of turbulence that could compromise fluid flow. When coupled with a male thread, it serves to connect to female-threaded components, ensuring a secure and leak-proof joint. This is particularly significant in applications where maintaining pressure and preventing leaks are paramount, such as in plumbing, heating, and industrial processes.

The use of stainless steel for these components enhances their durability and resistance to corrosion, making them ideal for various environments, including those exposed to moisture or chemicals. Stainless steel not only offers longevity but also maintains a clean aesthetic, which is often desired in decorative applications. The integration of a 90º bend with male thread in such settings allows for a seamless connection that complements both the functional and visual aspects of the installation.

From a practical standpoint, employing a 90º bend with male thread simplifies the installation process. In situations where space is limited, these fittings provide flexibility without requiring extensive modifications to the existing piping layout. This means that contractors can execute projects more efficiently, potentially reducing labor costs and timeframes.

Moreover, when designing piping systems, it's important to consider the flow characteristics of the liquids or gases being transported. A 90º bend can help maintain a steady flow rate, as opposed to a more abrupt change in direction, which might lead to increased friction losses. This consideration is crucial for maintaining system efficiency, particularly in large-scale installations or systems handling significant volumes.

In summary, the 90º bend with male thread is an indispensable component in stainless steel piping systems within the construction and decor industry. Its design not only facilitates effective directional changes but also contributes to the overall efficiency and reliability of fluid transport systems. When selecting materials and fittings for your projects, understanding the importance of these components will lead to better performance and longevity of the installations.

A 90º bend is designed to enable pipes to change direction smoothly, minimizing the risk of turbulence that could compromise fluid flow. When coupled with a male thread, it serves to connect to female-threaded components, ensuring a secure and leak-proof joint. This is particularly significant in applications where maintaining pressure and preventing leaks are paramount, such as in plumbing, heating, and industrial processes.

The use of stainless steel for these components enhances their durability and resistance to corrosion, making them ideal for various environments, including those exposed to moisture or chemicals. Stainless steel not only offers longevity but also maintains a clean aesthetic, which is often desired in decorative applications. The integration of a 90º bend with male thread in such settings allows for a seamless connection that complements both the functional and visual aspects of the installation.

From a practical standpoint, employing a 90º bend with male thread simplifies the installation process. In situations where space is limited, these fittings provide flexibility without requiring extensive modifications to the existing piping layout. This means that contractors can execute projects more efficiently, potentially reducing labor costs and timeframes.

Moreover, when designing piping systems, it's important to consider the flow characteristics of the liquids or gases being transported. A 90º bend can help maintain a steady flow rate, as opposed to a more abrupt change in direction, which might lead to increased friction losses. This consideration is crucial for maintaining system efficiency, particularly in large-scale installations or systems handling significant volumes.

In summary, the 90º bend with male thread is an indispensable component in stainless steel piping systems within the construction and decor industry. Its design not only facilitates effective directional changes but also contributes to the overall efficiency and reliability of fluid transport systems. When selecting materials and fittings for your projects, understanding the importance of these components will lead to better performance and longevity of the installations.

Latest News