Contact Information

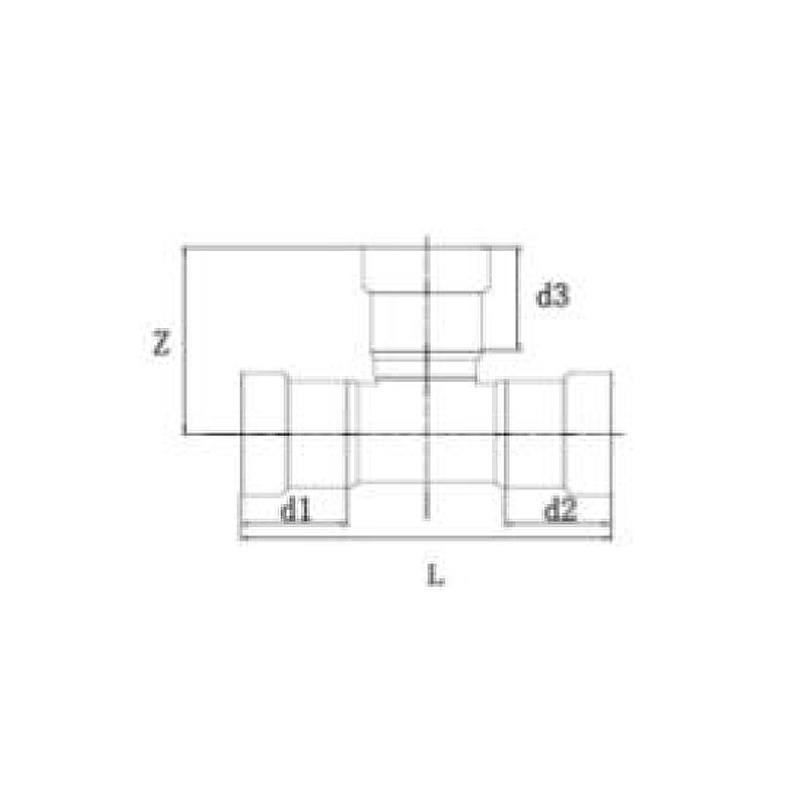

Reduced Branch Tee

E-mail: warrior.wang@zjipcpiping.com

Mobile/WeChat: +8613396691363

WhatsApp:+8613396691363

Product Description

Detail display

★ Product parameters

| Code EPDM | Code HNBR | Designator | L(mm) | Z(mm) | d1/d2(mm) | d3(mm) |

| 28611230013 | 28601230038 | 3/4”×1/2” | 112 | 51 | 30 | 26 |

| 28611240029 | 28601240037 | 1”×1/2” | 129 | 55 | 34.5 | 26 |

| 28611240030 | 28601240038 | 1”×3/4” | 129 | 60 | 34.5 | 30 |

| 28611250048 | 28601250045 | 1 1/4”×1/2” | 167 | 59.5 | 45.7 | 26 |

| 28611250049 | 28601250046 | 1 1/4”×3/4” | 167 | 64.5 | 45.7 | 30 |

| 28611250050 | 28601250047 | 1 1/4”×1” | 167 | 69 | 45.7 | 34.5 |

| 28611260066 | 28601260054 | 1 1/2”×1/2” | 176 | 62 | 47 | 26 |

| 28611260067 | 28601260055 | 1 1/2”×3/4” | 176 | 67 | 47 | 30 |

| 28611260068 | 28601260056 | 1 1/2”×1” | 176 | 71.5 | 47 | 34.5 |

| 28611260069 | 28601260057 | 1 1/2”×1 1/4” | 176 | 86 | 47 | 45.7 |

| 28611270085 | 28601270057 | 2”×1/2” | 196 | 69.5 | 49 | 26 |

| 28611270086 | 28601270058 | 2”×3/4” | 196 | 74.5 | 49 | 30 |

| 28611270087 | 28601270059 | 2”×1” | 196 | 79 | 49 | 34.5 |

| 28611270088 | 28601270060 | 2”×1 1/4” | 196 | 94 | 49 | 45.7 |

| 28611270089 | 28601270061 | 2”×1 1/2” | 196 | 96 | 49 | 47 |

| 28601280145 | 28601280124 | 2 1/2”×1” | 198 | 84.5 | 47.5 | 34.5 |

| 28601290145 | 28601280125 | 2 1/2”×1 1/4” | 198 | 99 | 47.5 | 45.7 |

| 28601280146 | 28601280126 | 2 1/2”×1 1/2” | 198 | 101 | 47.5 | 47 |

| 28601280147 | 28601280127 | 2 1/2”×2” | 198 | 103.5 | 47.5 | 49 |

| 28601290147 | 28601280128 | 3”×1 1/4” | 241 | 105.5 | 58.5 | 45.7 |

| 28601280148 | 28601280129 | 3”×1 1/2” | 241 | 107.5 | 58.5 | 47 |

| 28601290148 | 28601280130 | 3”×2” | 241 | 110 | 58.5 | 49 |

| 28601290150 | 28601280132 | 4”×1 1/2” | 314 | 120 | 79.5 | 47 |

| 28601280150 | 28601280133 | 4”×2” | 314 | 122.5 | 79.5 | 49 |

| 28601280149 | 28601290133 | 3×2 1/2” | 241 | 105.5 | 58.5 | 47 |

| 28601290151 | 28601280134 | 4”×2 1/2” | 314 | 118 | 79.5 | 47 |

| 28601280151 | 28601280135 | 4”×3” | 314 | 133 | 79.5 | 58.5 |

★ Specification

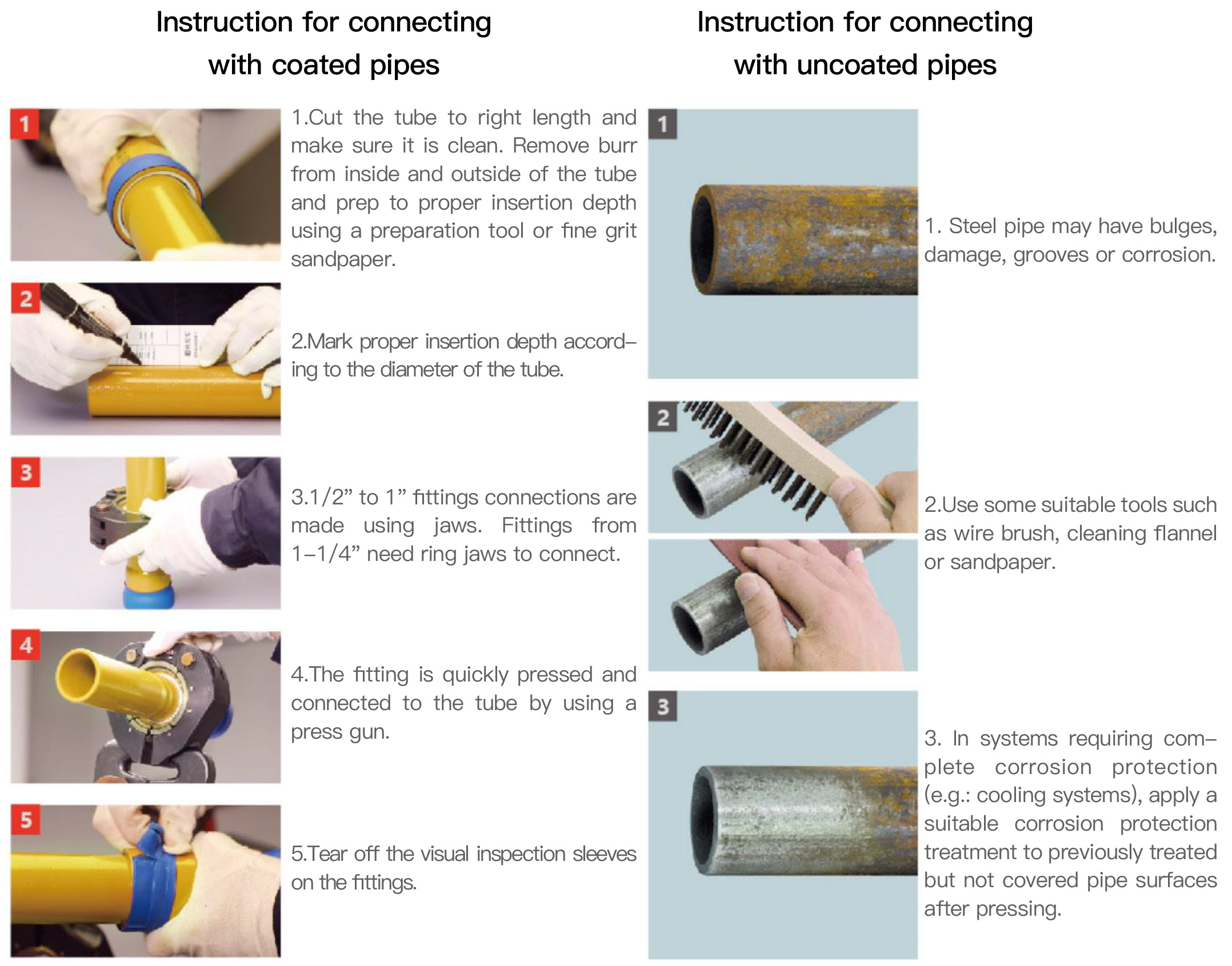

> Time save 60% than the traditional connection way(like welding, threading,grooving)

> Ecominic, both save installation time and labor cost

> No flame, cold connection

> Visual detection safety, reminding the press-missing by checking the plastic loop on the beads

★ Feature

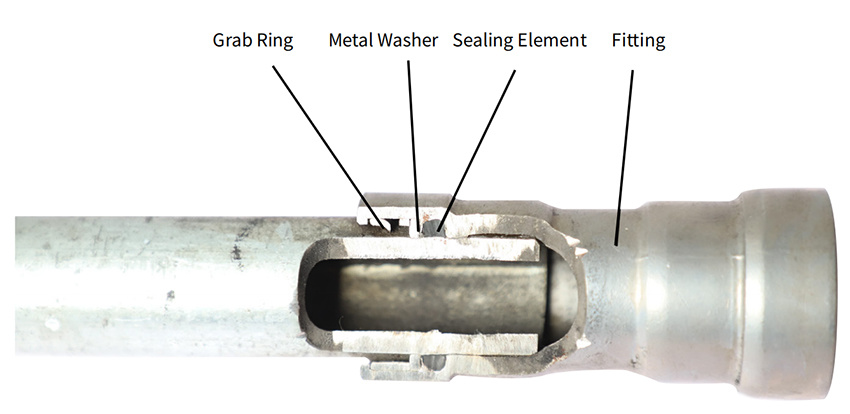

CB thick-wall carbon press fittings are designed with an innovative safety feature. The fitting will be leaked before press in the normal water pressure. Which may be eye checked by workers during the installation.

Sealing Elements design has been considered the compatibility to be connected with seamless, welding, zinc plating, industrial varnishes, epoxy resin coating, or black iron pipes. The thick and curve features on the sealing assures the fittings to be connected with these pipes tightly and securely

★ Application

GAS LINE

FIRE FIGHTING AND SPRINKLER

HEATING AND COOLING

COMPRESSED AIR DELIVERY

★ Manufacturing Capability

The production of pipes and pipe fittings,all the core processes are completed in our own factory(tube making,cutting,expanding,tube bending,forming,punching,welding, chamfering, pressure testing,acid cleaning & passivating ,coating)

Keyword:

Reduced Branch Tee

Categories:

You May Like

Qualification certificate

Company Album

Get A Quote

Tell us more so we can connect you with the right person for your request.